Enquiry

Provide your designs with specific details (size / quantity/ fitting and colors etc.) stated clearly, then we can quote you the best unit price and mold charges accordingly.

How to Place an Order?

Before place the order, as we do customer’s design only, please offer us the artwork of YOUR design (logo) / size / quantity and colors etc. specification details, then we can quote you accordingly.

Please fill out the inquiry form on the individual product page or on contact us page; you can also send email to us at inquiry@promotionalgift4u.com

We recommend you to fill out the inquiry form on our site, which can insure that we receive your inquiry. Because if you send an email directly, sometimes it will be classified as spam by outlook.

Payment Method

Due to the permanency of imprints on custom products, all first-time orders must be paid for prior to production. We accept payment method such as credit card, T/T, LC. We welcome purchase orders from government agencies and large organizations.

T/T Remittance

L/C Letter of Credit

Credit Card

How to subscribe or cancel the subscription of monthly promotional product newsletter?

Need more idea of promotional giveaways for you next upcoming event? Feel free to fill out your email address at below form, we will send you our latest product information for you every month, help you to inspire more ideas!

Subscribe EDM

In case you don’t need promotional product leaflet in the future, just confirm your email address for non-inclusion, we shall remove your e-mail from our database. You won’t receive the newsletter next month.

Cancel EDM

Artwork Requirement

Vector art such as “EPS” or “AI” or “CDR” or “PDF”

Avoid font deformed, convert text to outlines. If working with Adobe Illustrator, to convert text, click on “Type” in the top menu bar. Then, select “Create Outlines” and save.

Specify PMS number of each color (Except CMYK/ offset printing artwork)

Specify the product full size in the artwork.

Customization Guidelines & FAQs

Discover the full range of customization possibilities for different materials.

Our FAQs cover leather pattern swatches, metal plating finishes, embroidery thread colors, and various logo application methods—helping you create high-quality, brand-specific products.

Compare plating options, surface textures, logo techniques, and attachment types for your metal orders

What metals and grades do you offer?

We’ll recommend by design complexity, weight target, and budget.

Which manufacturing process suits my design?

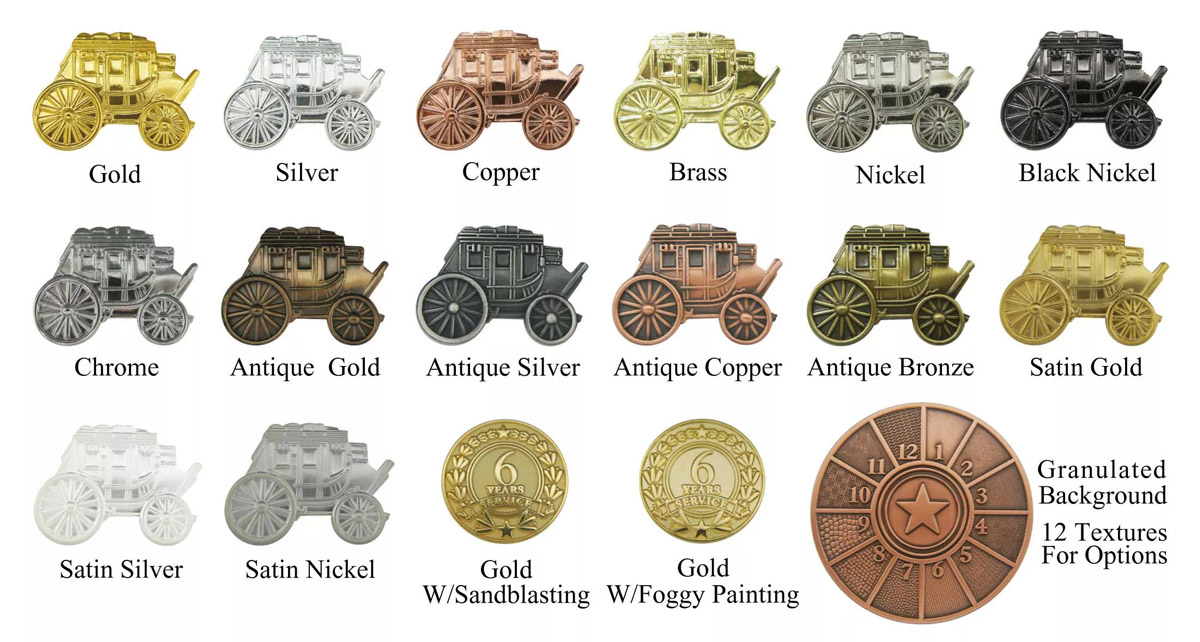

What metal finishes can I choose from?

We offer a wide selection of electroplating finishes, including:

Our Electroplating Chart provides visual samples for reference before production.

Electroplating Chart for Metal

Can you do two-tone or selective plating?

Yes. Dual plating (e.g., gold + nickel), selective/spot plating, and antique washes to highlight relief are available. Masking may add cost/lead time.

What surface textures and post-finishes are available?

High polish, satin/matte, brushed, sandblasted/frosted, stone-wash, hammered. Texture can boost contrast, hide fingerprints, or reinforce a rugged look.

What logo effects can be applied to metal products?

Soft Enamel, Hard Enamel (Cloisonné), Etching/Laser Engraving, Silkscreen/Pad Printing, UV Digital Printing (photo-level), 3D Casting. Optional epoxy dome for a glossy, protective top.

Can you match my brand colors on metal products?

Yes. Pantone-guided matching for enamel fills and print inks; selective color plating on request. Minor variance may occur across different finishes and batch lots.

What thickness and weight should I choose?

Typical ranges: Badges/coins 1.5–3.5 mm, Nameplates 0.5–1.5 mm. Heavier parts feel premium but raise shipping cost. We’ll balance thickness, durability, and budget.

What backings and attachments are available?

We can custom-mold hardware and add bottle-opener or multi-tool features.

What files do you need to start?

Kindly include Pantone color references, plating/finish details, and clear call-outs for recessed and raised areas.

Can I approve a sample before mass production?

Yes. Digital proof first; pre-production physical sample available to verify color, relief, and attachment. Sampling may add time but reduces risk.

What affects price and lead time?

Material & thickness, part size, plating type (single vs dual), logo effect (soft enamel/hard enamel/3D/printing), number of colors, attachments, packaging, quantity, and rush service.

Do you support compliance and testing?

We can produce to RoHS/REACH material specs, offer lead/nickel release controls for skin-contact, and provide test reports when required.

Everything you need for leather customization: patterns and colors, logo techniques, edge & stitch styles, lining/structure options, and branded hardware

What leather patterns can I choose from?

We offer smooth, pebble, saffiano, cross-grain, vintage pull-up, and suede textures. Request digital photos or physical swatches for approval before production.

Leather Pattern Swatches

Can you match my brand’s leather color?

Yes. We provide Pantone-guided color matching or selection from in-stock swatches. Slight variance may occur due to dye lots and texture. Color-dyed leather may affect lead time/MOQ.

Pantone Color Matching for Custom Orders

What leather logo effects are available?

We offer several logo branding techniques for leather products, we will advise the best method by logo detail and usage.

Which leather grades & types are available?

Full-grain (premium, natural marks), top-grain (refined surface), split/suede, and corrected-grain. We also supply PU/microfiber “vegan” leather on request for cost or compliance needs.

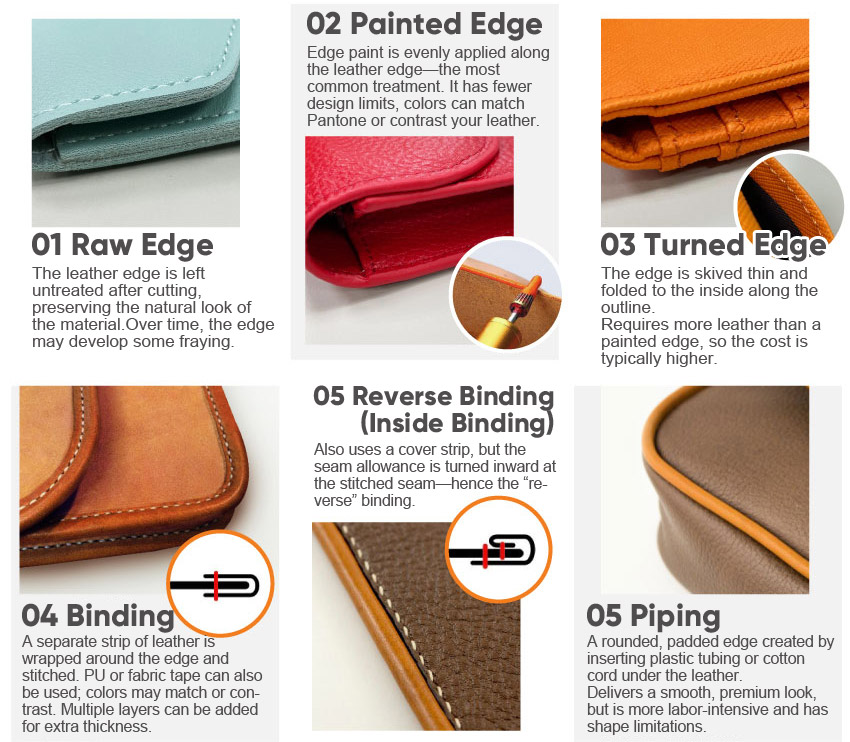

What edge finishes do you offer?

Our two most commonly used edge finishes are below two:

Common Leather Edge Finishing Methods

Can you add lining or structure?

Yes—microfiber suede, cotton/poly twill, PU lining, or no-lining minimalist builds. We can add interlining/stiffeners, foam padding, or board to control shape, protection, and thickness.

What hardware finishes and attachments are available?

Custom molds and standard parts (snaps, rivets, D-rings, buckles, zippers). Finishes include gold, nickel, black nickel, antique brass, copper, gunmetal, and color-coated. Hardware can be laser-marked or engraved.

What size tolerances should I expect?

Typical production tolerance is ±1–2 mm depending on item size and construction. Tight tolerances may require tooling or design adjustments.

Leather Manufacturing Process | Cutting, Stitching & Logo Branding

We deliver high-quality leather craftsmanship through a rigorous production process—from precision cutting and professional stitching to refined edge painting. Elevate your brand with our custom logo debossing and foil stamping services.

We ensure consistent quality, flexible customization, and dependable lead times.

Your quick reference for fabric swatches, thread colors, stitch & logo techniques, and attachments

What base fabric types do you offer for embroidery?

We offer twill (most common for patches), felt (soft and matte), canvas/duck (rugged), and specialty fabrics such as reflective or ripstop. Choose twill for crisp logos, felt for softer branding, and canvas for a durable, workwear feel.

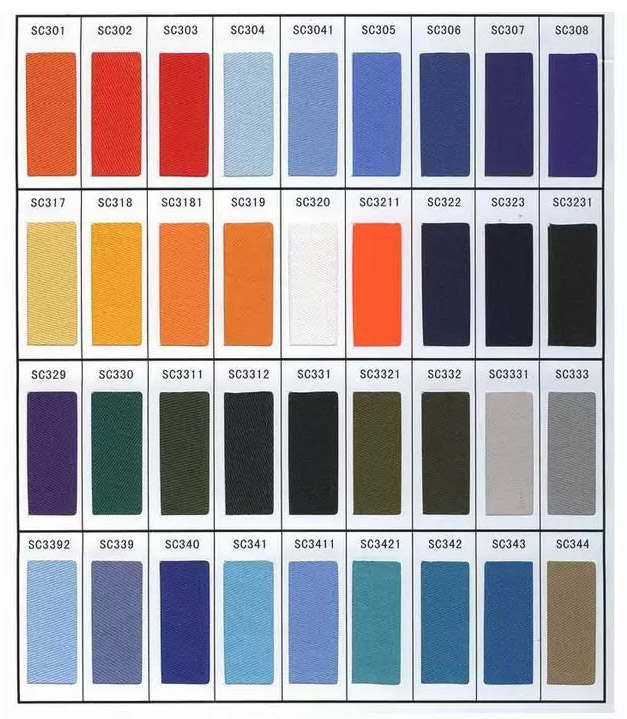

Can you match the base fabric color to my brand?

Yes—choose from our standard swatches or request near-match to Pantone. Please note minor shade tolerance due to dye lots and screen variations.

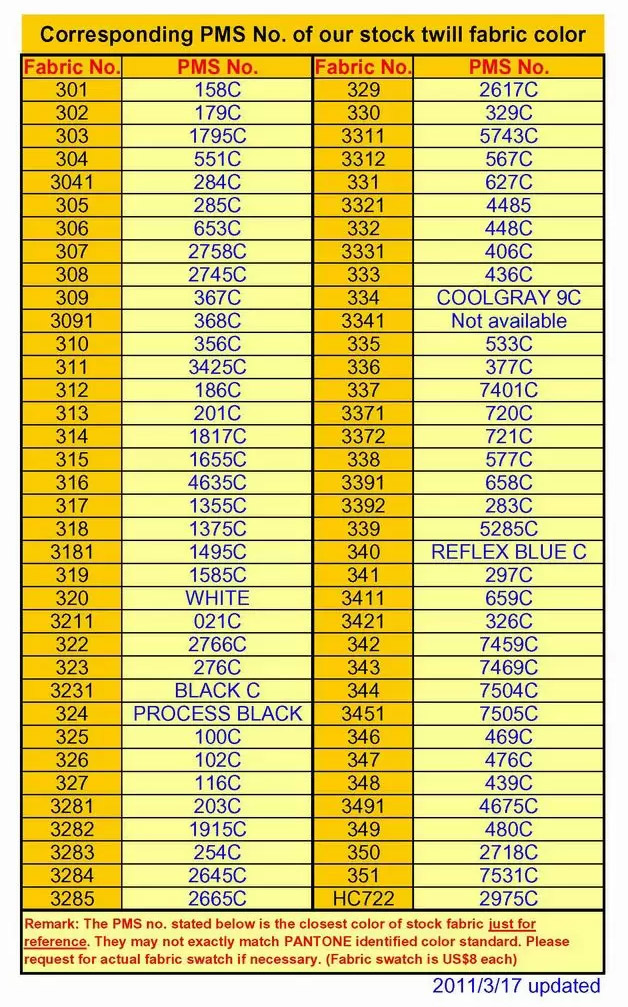

Pantone ↔ Fabric Color Reference (Stock Twill)

This chart shows the nearest Pantone (PMS) reference for our stock twill base fabrics. Actual shades may vary by dye lot, weave and lighting. For critical branding, please request a physical swatch or ask about custom-dyed fabric (MOQ/lead time apply).

Pantone to fabric color chart for stock twill – embroidery base fabric reference

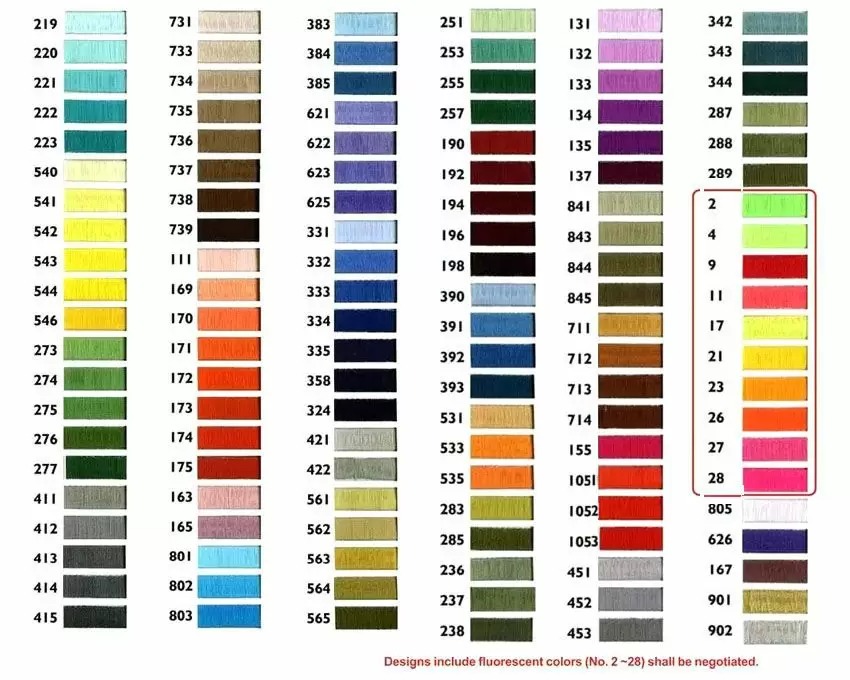

Do you provide a thread color chart and Pantone matching?

Yes. We offer over 250 thread color options and offer Pantone-guided matching. Exact 1:1 Pantone matches aren’t always possible, but we will confirm the closest approved shade.

What thread materials are available?

Polyester (colorfast, UV-resistant), Rayon (silky sheen), Metallic, Neon, Glow-in-the-dark, and Fire-resistant threads are available. Specialty threads may affect lead time and cost.

How many thread colors can one design include?

How do you handle complex, gradient, or photo-level designs?

Thanks to our latest print tech, we offer Heat Transfer and Smart Printing so even highly complex artwork can be reproduced cleanly. We can also do print + stitch hybrid to keep the tactile look of embroidery while preserving fine details.

Custom Embroidery Patch with Full Color Smart Printing

Custom Embroidery Patch with Dye Sublimation Printing

What backing options are available?

Sew-on (no adhesive), iron-on/heat-seal, hook-and-loop (Velcro®), and peel-and-stick temporary adhesive. Iron-on is quick; hook-and-loop is removable; sew-on offers maximum durability.

Which backing should I choose?

For uniforms and gear that will be washed often, pick sew-on or hook-and-loop. For giveaways or short-term use, peel-and-stick works well.

Borders & Edge Finishes (for patches)

Merrowed border (classic overlock edge) for standard shapes, and heat-cut/laser-cut edge for complex die-cut shapes or tight corners.

Privacy Policy

Jin Sheu values the privacy rights and interests of every customer. When handling your personal information, we adhere to fair and lawful practices. The security of personal data is a top priority for us. We aim to keep you informed about the storage, type, and usage of your data.

Click to learn more: Privacy & Cookie

Return Policy

Immediate quality control is the necessary procedure after goods arriving your office or warehouse, or at least check it before you dispatch them to your clients. If the claims requested after goods been used, we won’t be responsible for it, especially for the plating fade out, scratching or mechanism function failure as we have no idea about the way of usage; if the goods stored within 6 months after the invoice date and the packing remained closed, we will be responsible for the claims, but we need your kind cooperation before discount offered or returned for fixing or reproduction for replacement.

We believe there are countless different situations for claims and it is hard to name all the circumstances, just simply stress the major issues we need you be cooperative. The more collaborative we are, the sooner the claims solved.