Custom ABS Car Emblems

Custom Self-adhesive 3D ABS Car Emblem Decal Stickers Wholesale

ABS Car Emblems are the industry-standard choice for automotive branding, offering a lightweight and durable alternative to metal for outdoor applications. Designed for custom logos, non-OEM branding, and aftermarket projects, ABS emblems provide a cost-effective solution for scalable production without compromising appearance or performance.

Production and export of original OEM emblems require an official Letter of Authorization.

Have a design in mind? Send us your artwork or concept, we provide full OEM support, including mold development, sampling, and bulk production. Our team assists with material selection, construction recommendations, and finish options to ensure your emblem meets both design and application requirements.

TABLE OF CONTENTS

PID 6286|CUSTOM ABS CAR EMBLEM SPECIFICATIONS

- Logo Shape: Custom ABS injection-molded shape based on your logo outline

- Dimensions: Typically 5–20 cm

- Thickness: Generally 3–5 mm (adjustable based on design)

- Color System: Pantone (PMS) matching or customer-provided color samples

- Finishes: Chrome plating, metallic effects, matte, gloss, brushed textures

- Backing Options: Mounting posts or automotive-grade adhesive

- Packaging: Individual polybags or custom trays, boxes, labels, and barcodes for warehouse systems

- MOQ: 500 pieces per design

DETAILS

Why Choose ABS for Car Emblems?

- Significantly lighter than metal, reducing stress on vehicle surfaces and lowering shipping costs for bulk orders

- Lower unit cost in mass production, ideal for medium to large production volumes

- Excellent surface quality for chrome plating, painting, paint filling, and printing

- Stable performance for outdoor use, including high-temperature environments

- More cost-effective over the product lifecycle, despite higher upfront mold tooling investment

- Proven by long-term use in hot-climate markets such as the Middle East.

Different Manufacturing Methods for Custom ABS Car Emblems

Custom ABS Decals/ ABS Car Labels/ ABS Auto Emblems can be manufactured using different structures and finishing techniques depending on logo complexity, color requirements, depth, and budget. Below are the most common ABS nameplate construction methods used in automotive branding and custom projects.

1/ One-Piece Injection Molded ABS Emblem with Chrome Finishing

Ideal for Logos with Simple Shapes and Clean Outlines

- One-piece ABS injection molding

- Clean, solid structure

- Suitable for single-color or plated finishes

- Cost-effective for large-volume production

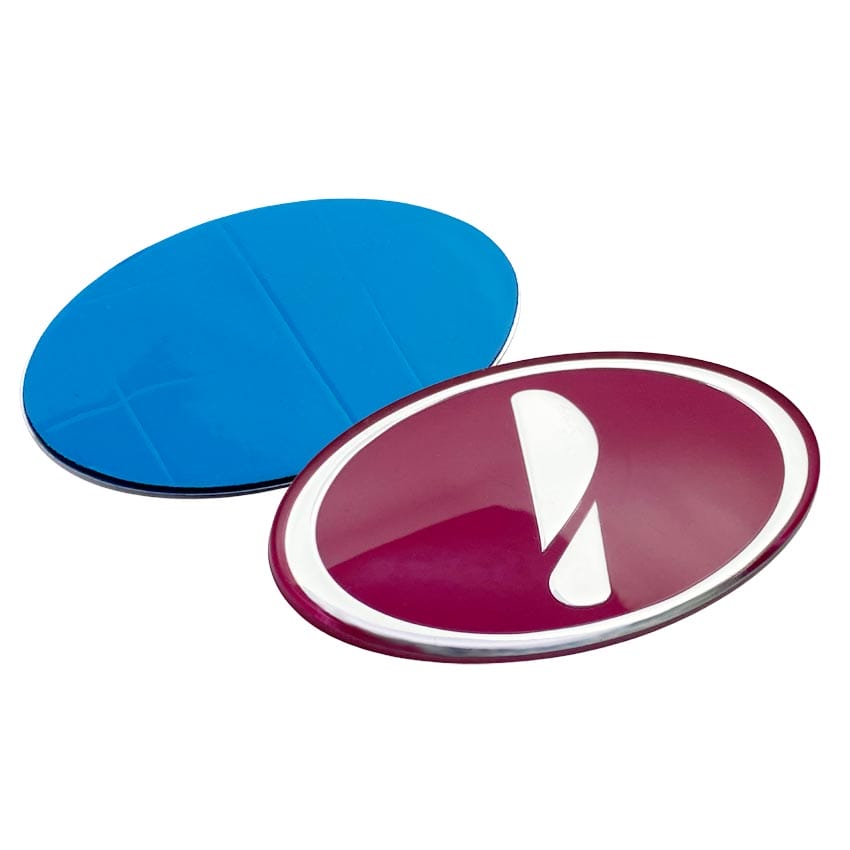

2/ Injection Molded ABS Emblem with Electroplated Finish

Recessed Details with Hand-Applied Black Paint Filling

- Injection-Molded One-Piece ABS Structure

- Electroplated Metallic Surface

- Recessed Areas with Black Paint Fill

- Clean Edges and Fine Detail Definition

3/ ABS Car Decals with Color Foil Stamping

Black Base Coating with Secondary Color Highlighting

- Precision Injection-Molded ABS Structure

- Black Base Paint Application

- Color Foil Stamping on Raised Areas

- Bold Contrast for Graphic Logos

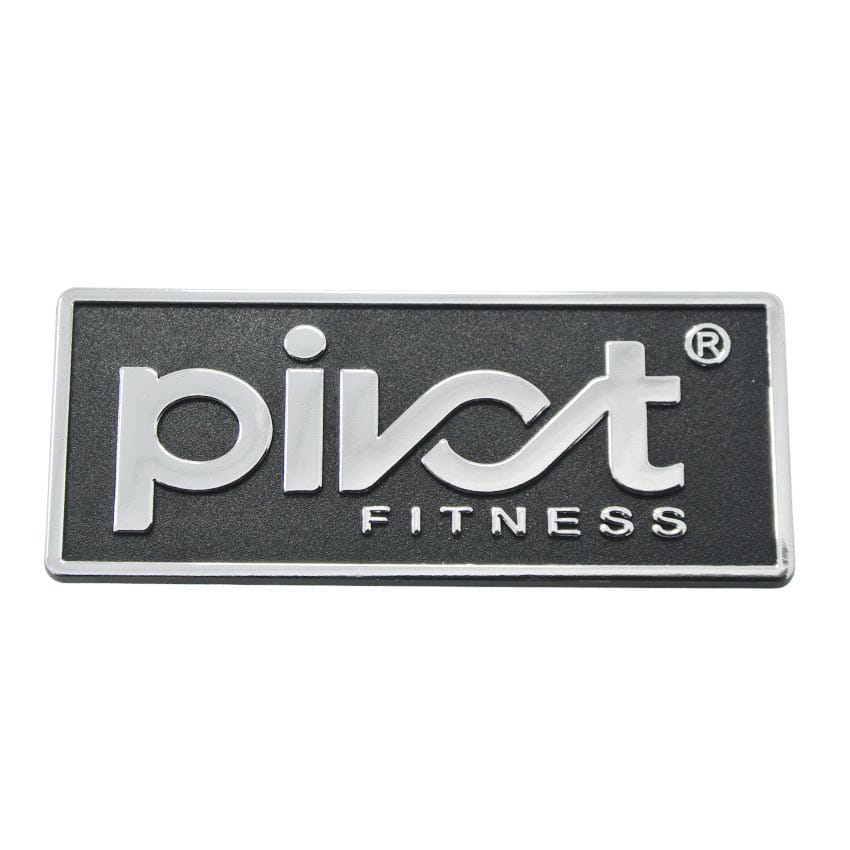

4/ ABS Car Rear Emblem Stickers

Multi-Piece Emblem with Positioning Foam

- Individual ABS components

- Precise spacing during installation

- Flexible layout for complex logos

- Ideal for lettering-style designs

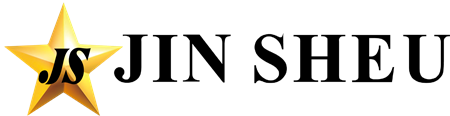

5/ ABS Base + Acrylic Overlay Badge

Protected Printed Graphics with Premium Depth

- ABS structural base

- Acrylic overlay for graphic protection

- Printed artwork sealed beneath acrylic

- Optional 3M™ adhesive backing

6/ ABS Emblem with Inset Lettering

High End Three-Mold Construction

- Black-Painted ABS Base

- Inset Letter Assembly

- Mixed Surface Finishes-The “SPORT” lettering is painted red, while the “TRD” lettering is finished in satin silver electroplating, creating a layered and premium visual effect.

Custom ABS Car Decals Manufacturing & Finishing Overview

Injection-Molded One-Piece Construction

ABS car emblems are produced through injection molding, where molten ABS is injected into a custom mold and solidified into a single integrated structure.

Hollow or cut-out areas are formed in one piece, ensuring consistent strength and clean edges.

- Standard thickness: 3–5 mm

- Raised areas can be thickened based on logo design

- Suitable for complex 3D shapes and fine details

Electroplated Metallic Finishes

Custom ABS car emblems can be electroplated in a wide range of metallic finishes to achieve different visual effects and durability levels. Plating duration can be adjusted to 24 / 48 / 72 hours, with 48 hours as the standard option, offering approximately 3–5 years of color durability under normal outdoor conditions.

👉 Please select your preferred electroplated finish from the color chart below.

- Longer plating time = better color retention and durability

- Finish options: Glossy or Matte (Satin)

- Metallic tones can be customized based on appearance requirements and budget considerations

The color chart below shows commonly requested finishes such as Gold, Real Gold, Dark Gold, Rose Gold, Antique Brass, Silver, Matte Silver, and Chrome. Actual color tone may vary slightly depending on plating duration and surface texture.

PRODUCT VIDEO

Custom ABS Car Emblems for Automotive Branding

ABS is the industry-standard material for automotive emblems, offering a lightweight yet durable alternative to metal. Our custom ABS car emblems are designed for automotive branding, non-OEM projects, and aftermarket applications, with flexible options for shape, thickness, finishes, and mounting.

With full OEM support, we assist global B2B clients from mold development to bulk production.

Send us your design at inquiry@promotionalgift4u.com to receive professional technical feedback and a production plan for your custom ABS car emblem project.

This FAQ answers common questions about custom ABS car emblems, covering materials, finishes, durability, MOQ, and production to help you prepare your inquiry efficiently.

What material is used for custom ABS car emblems?

Our car emblems are manufactured using automotive-grade ABS plastic, the industry-standard material for lightweight, durable automotive badges. ABS provides excellent surface quality for plating, painting, and printing while remaining suitable for outdoor use.

What sizes and thicknesses are available?

- Standard sizes typically range from 5 cm to 20 cm, depending on logo design and application.

- The usual thickness is 3–5 mm, with raised logo areas adjustable for enhanced 3D depth.

Are ABS car emblems suitable for outdoor and high-temperature environments?

Yes. ABS car emblems are designed for outdoor automotive use and perform reliably in high-temperature conditions. Our products are widely supplied to hot-climate markets such as Saudi Arabia and Israel, where heat resistance is a key requirement.

What surface finishing options do you offer?

We provide a wide range of finishes, including:

- Chrome and metallic electroplating

- Matte or glossy surfaces

Finish options can be selected based on appearance, durability requirements, and budget.

How durable are electroplated ABS emblems?

The durability of electroplated ABS emblems depends on the plating duration selected. We offer 24-hour, 48-hour, and 72-hour electroplating options to meet different performance and budget requirements.

- 24-hour electroplating: Suitable for budget-sensitive projects; the finish typically lasts approximately 1–2 years under outdoor conditions.

- 48-hour electroplating (standard): Our default option, providing approximately 3–5 years of color durability for most outdoor applications.

- 72-hour electroplating: Recommended for high-quality or long-term outdoor use, offering up to 5–7 years of color durability.

Our team can recommend the most appropriate electroplating option based on your application, expected service life, and budget.

What backing or mounting options are available?

Common mounting options include:

- Automotive-grade self-adhesive backing

- Foam adhesive

- 3M™ adhesive (optional)

- Mounting posts (design-dependent)

Our team can recommend the most suitable option based on application and surface type.

Do you support custom logos and non-OEM designs?

Yes. We fully support custom logos, non-OEM branding, and aftermarket designs.

Please note that original OEM car brand emblems require an official Letter of Authorization for production and export.

What is the minimum order quantity (MOQ)?

The standard MOQ is 500 pieces per design.

For special projects or multiple designs, please contact us to discuss feasibility.

What is the typical production lead time?

Lead time depends on design complexity, finishing method, and order quantity.

In general:

- Mold development: approx. 20–25 days

- Mass production: approx. 25–30 days after sample approval

Exact schedules will be confirmed during the RFQ process.

What packaging options are available?

Standard packaging is individual polybags.

Custom packaging options include trays, boxes, printed labels, and barcodes compatible with warehouse systems.

How do I request a quotation?

Simply send us:

- Your logo or artwork

- Target size and quantity

- Preferred finish and mounting option

- Application details (exterior or interior use)

Our team will review your requirements and provide technical feedback and a detailed quotation.

JIN SHEU

JIN SHEU JIN SHEU

JIN SHEU